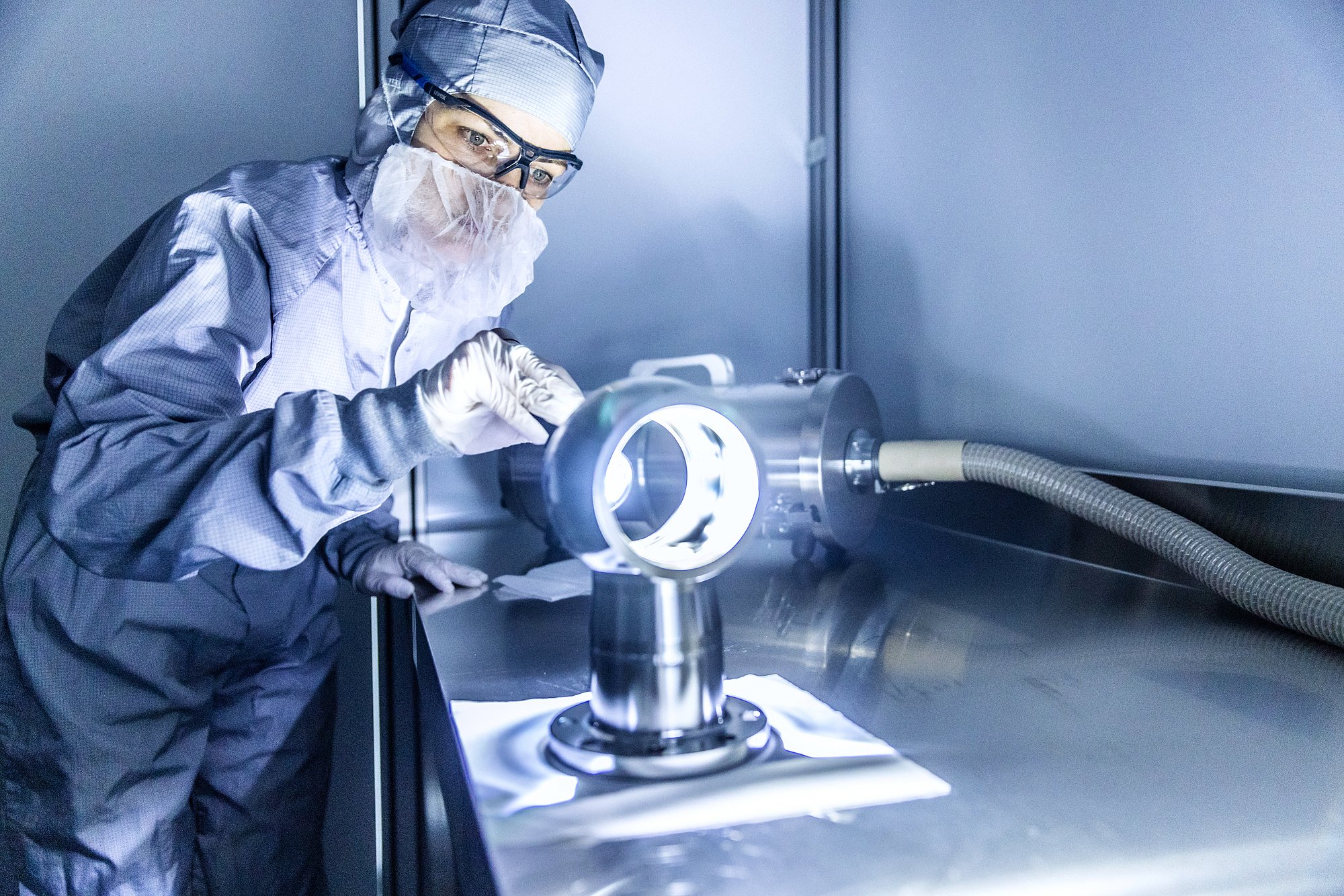

As a system supplier, we offer tailor-made solutions for highly specialised future industries in which high-precision manufacturing options, assembly and commissioning under clean room conditions are essential. Thanks to the equipment and dimensions of our clean rooms, we guarantee the highest quality and flexibility throughout your entire project.

An overview of all our clean room related services can be found here:

Clean room brochure

![]() Design & Development of Vacuum Systems

Design & Development of Vacuum Systems

![]() Inhouse Manufacturing up to 50 t

Inhouse Manufacturing up to 50 t

![]() Automation Technology

Automation Technology

![]() Assembly & Testing up to ISO 5

Assembly & Testing up to ISO 5

![]() On-Site Installation & Service

On-Site Installation & Service

Component dimensions

STREICHER cleanrooms: 1,407 m2

Test methods